Iterative (Physical) Design: A Mount For My TRMNL

On the recommendation of Casey from ATP, I recently picked up a couple of TRMNL E-Ink displays. They're really neat little gadgets - a simple E-Ink display that syncs with all of your favorite services to display info in a clean and simple manner. I've only had mine for a month now, but I've loved having Github stats, Todoist lists, and my calender displayed on my desk. They also have a pretty robust developer framework for writing your own plugins. I'll be digging into that real soon. If you have any interest, they set me up with a referral code (sethangell) that gets you $10 off.

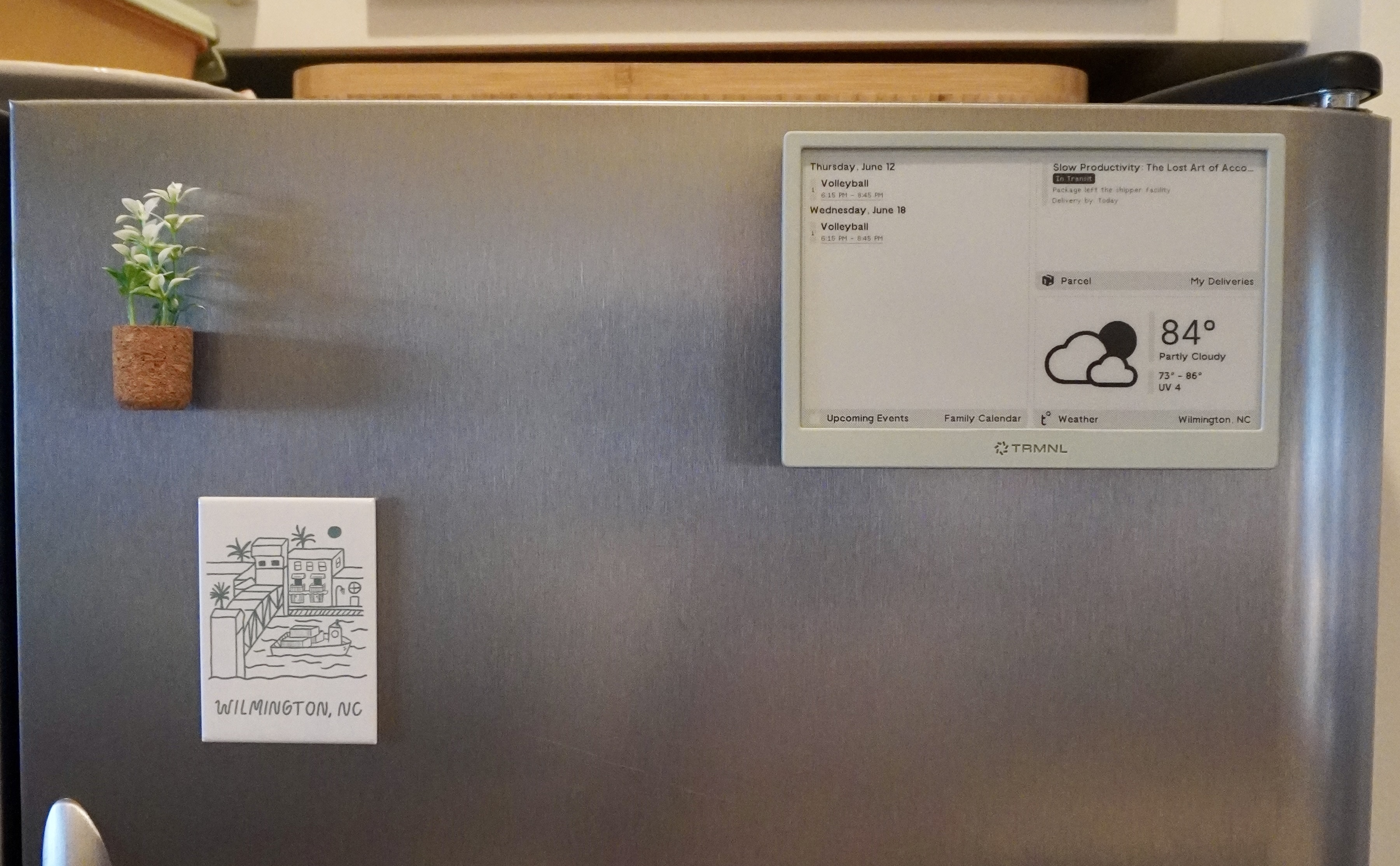

While I love the TRMNL on my desk, I really wanted the second device to act as more of a "Family Status Board" in our kitchen. For a variety of reasons (mostly Maddi and I's love for single-use appliances), counter space is a bit limited. But you know what was surprisingly empty?

The fridge. 15 square feet of magnetic surface, ripe for the taking.

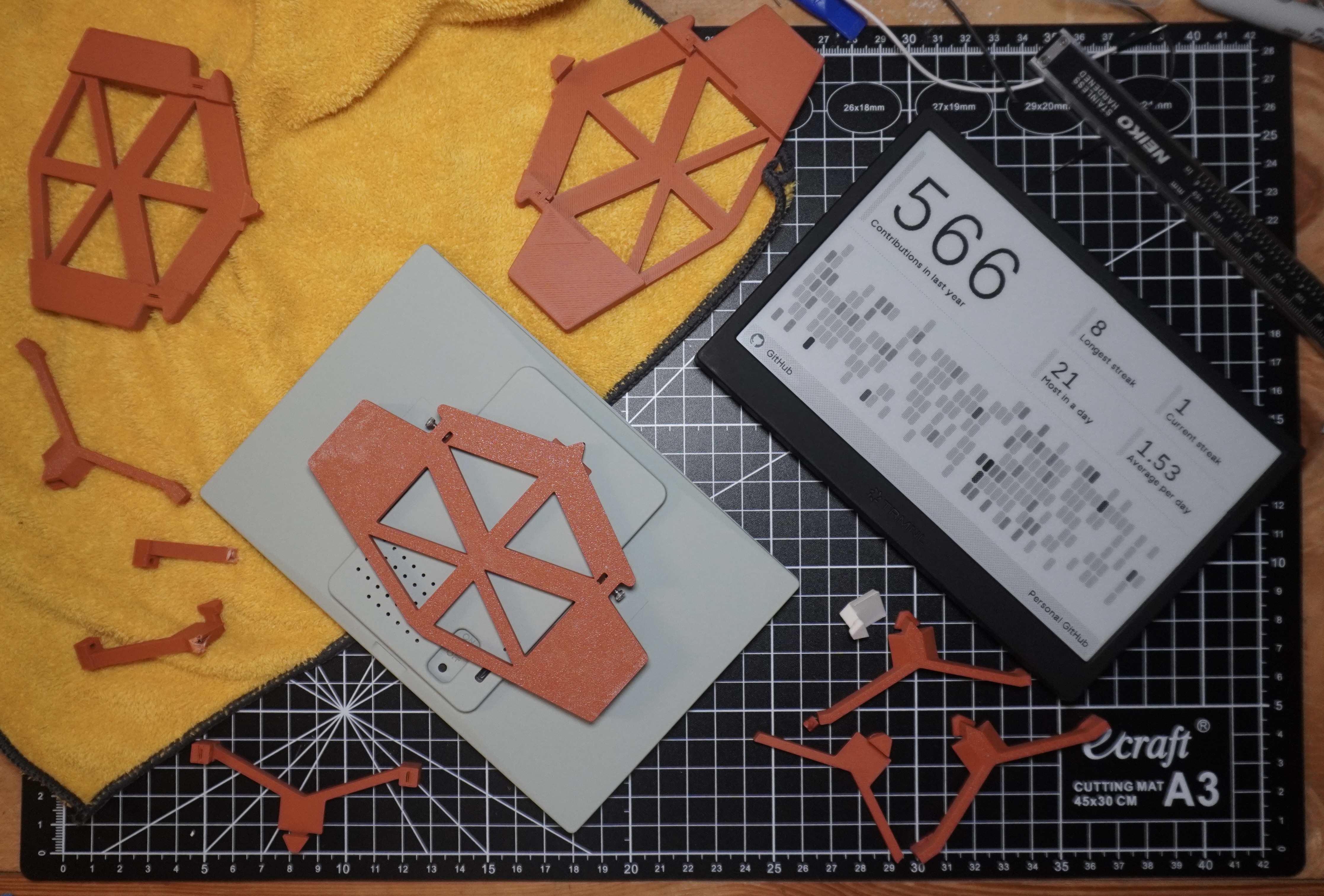

I was really excited to work on this mount. I've dabbled in 3d printing for the last five years or so, but I only got serious about learning Fusion360 in the past couple months. Now given my day job as a software engineer, I'm already well aware of the joys that a tight feedback loop can bring. It's part of the reason frontend development can be so fun (or painful depending on the day).

However, there is something so satisfying about that iterative development which generates a physical object each time! With how fast my P1S prints, my cycle time from Fusion360 export -> test fit on the TRMNL was like 15 minutes. This was great for getting all of the dimensions dialed in.

In the end I'm pretty happy with the result. Magnets are embedded within the model which attach to the fridge, and utilizes 3 points of contact to secure the mount to the back of the display. You can check it out here.